Basic Info

| Model NO. | GMU400 |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.02~0.03(mm) |

| Performance Classification | Economical CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Product Name | 5 Axis CNC Machining Center |

| Model | Gmu-400 |

| Keywords | 5axis Machining Center |

| X/Y/Z-Axis Travel | 450/500/350 mm |

| A/C-Aixs Travel | +/-120/360 Deg |

| Spindle Nose to Table | 150-500 mm |

| Table Size | 0400 mm |

| Maximum Load Bearing | 120 Kg |

| Maximum Spindle Speed/Taper Shank | 30000/Hsk-E40 Rpm |

| Spindle Power (S1/ S6 - 40%) | 10/13 Kw |

| Torque (S1/ S6 - 40%) | 5.5/7.1 N.M |

| X/Y/Z-Axis Rapid Feed | 30/30/20 M/Min |

| Maximum Cutting Feed Rate | 10 M/Min |

| Acceleration | 5 M/S2 |

| Number of Tool Positions | 16t |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | JTC TOOL |

| Origin | Guangdong, China |

| Production Capacity | 10000set/Month |

Product Description

DONGGUAN JTC TOOL CO., LTD.JTC TOOL Delem CNC Control System 5 Axis CNC Machining For Aluminium Parts GMU400 5 Axis Horizontal Milling Machine China 5 Axis Turn Mill Machining Center Product Description

Achieve High-Accuracy Five-Axis Simultaneous MachiningFeaturing A High-Rigidity Fixed Beam Gantry Structure, The GMU-400 Fearless Series Can Realize High Machining Performance And Contour Accuracy Under Highly Dynamic Conditions With High Accuracy, Performance, And Efficiency. More importantly, The GMU-400 Is Equipped With Outstanding GTRT Gear Transmission Cradle Technology As Well To Present An A-Axis Torque Of 1056N.M And A C-Axis Torque Of 432N.M. From Any Difficult-To- Cut Material To The Highest Surface Quality Required By Mold Manufacturing And Even The Nearly Exacting Contour Accuracy, The GMU-400 Fearless Series Can Deal With Them PerfectlyBorn For The FutureThanks To The Persistence Of European Technologies, We Have Mastered The Core Technologies Required To Continuously Promote The Technological Innovation Of A Self-Owned Brand. With A Powerful Technical Engine, We Can Provide A Productive Overall Solution That Is Capable Of Machining Efficiently For Customers Engaged In The Milling Processing Of All Kinds Of Complex High-Precision Parts And Molds, Etc. The GMU 400 5-Axis Machining Center, Has Gathered The Powerful European Five-Axis Simultaneous Milling TechnologyAdvantage- High-Accuracy Milling Technology- High-Rigidity Be Structure- High-Performance Spindle Technology- GTRT Gear Transmission Rotary Table Technology- High-Response Dynamic Performance- Inheriting Exquisite German Crafts- Presenting Powerful And High-Accuracy Machining Performance

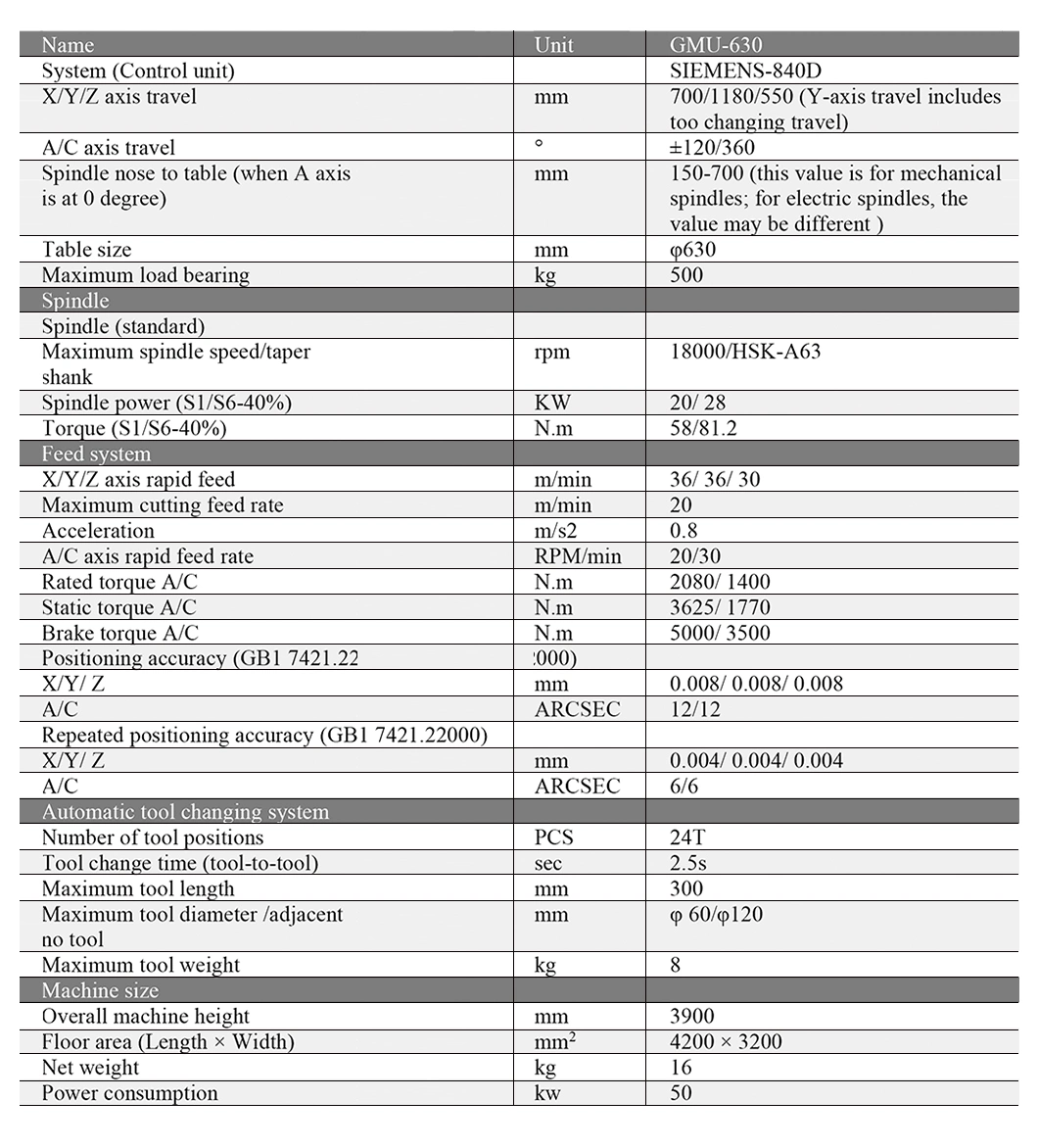

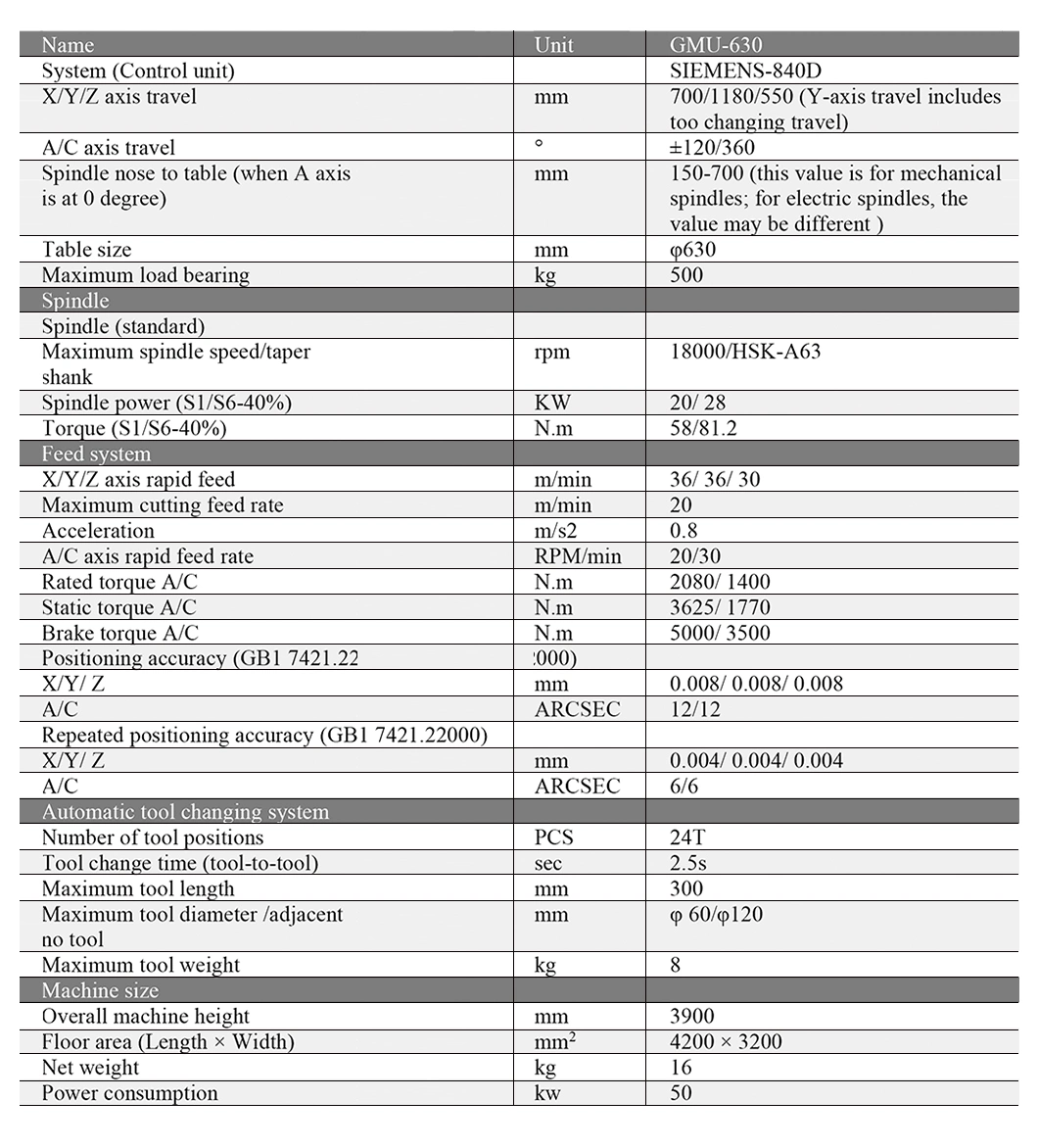

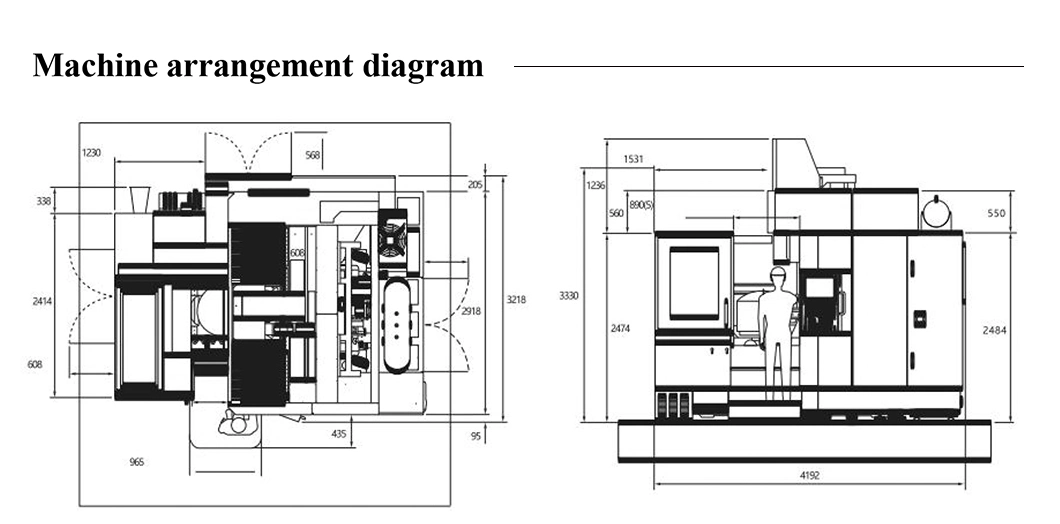

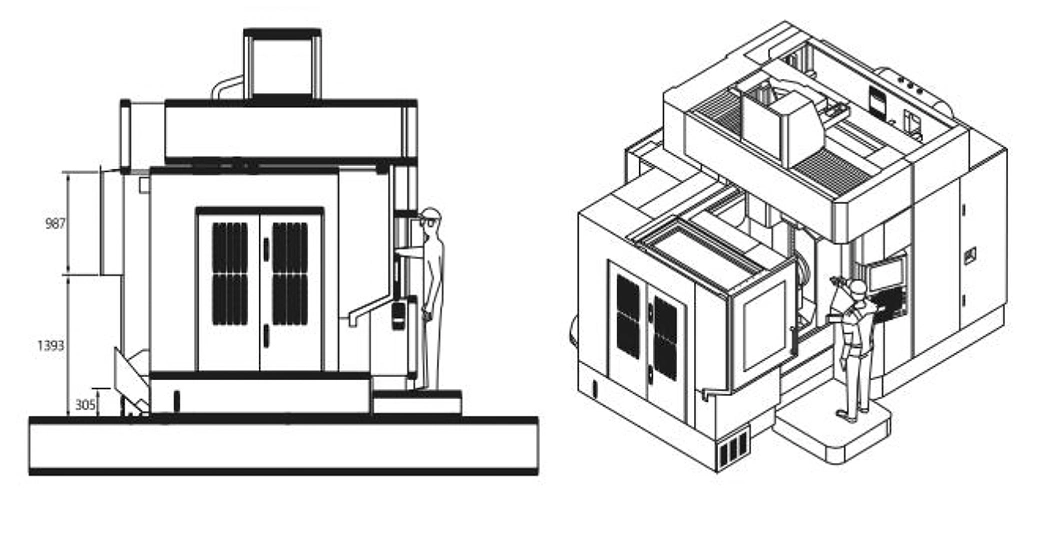

Product Parameters

Detailed Photos

FAQ

What equipment can you get from our Factory?* Milling machining center:Vertical Machining CenterHorizontal Machining CenterDrilling machineEngraving and milling machineGantry type machining center* Turning center:Double-spindle turning and milling centerDouble-spindle double-lane turning and milling compound centerCNC turning and milling compound centerTurning and milling compound center (true Y-axis power turret)* Turning center:CNC46C turning and milling seriesCNC46D Turret SeriesCNC46 gang knife seriesFlat bed CNC lathe* Five-axis machining center* CNC machining part* CNC ToolsWe support customization of the machines you need and provide you with good after-sales service.WHY CHOOSE DONGGUAN JTC TOOL CO.,LTD?QUALITY & RELIABILITYfirst time delivery.Quality cannot be inspected into a product. With that in mind we have a total quality mindset,throughout every process. Every person takes responsibility, there are no excuses. Certified to ISO 9001 SGS and with extensive quality procedures, we have been audited and certified by many authority agency companies in different industry sectors.QUICK RESPONSEWe recognise that in today's market, all companies are looking to reduce their margins with leaner production. With extensive machine resource, various add on services plus delivery and logistics to suit any requirement, you can be assured of our flexibility in offering a highly responsive and quick service. We have a proven track record of meeting and exceeding customer expectations.ADVANCED SYSTEMS & TE CHNOLOGYWe recognise that communication is the key and are working towards being a true Industry 4.0 Smart Factory with the latest IT hardware and our own in-house developed advanced ERP software. Such advanced systems will aid communication between us, the machine technology and you the customer, allowing us to be even more responsive to your requirements.Using the latest technology and specialist project management, we offer exceptional local serviceand performance on a national scale.