Basic Info

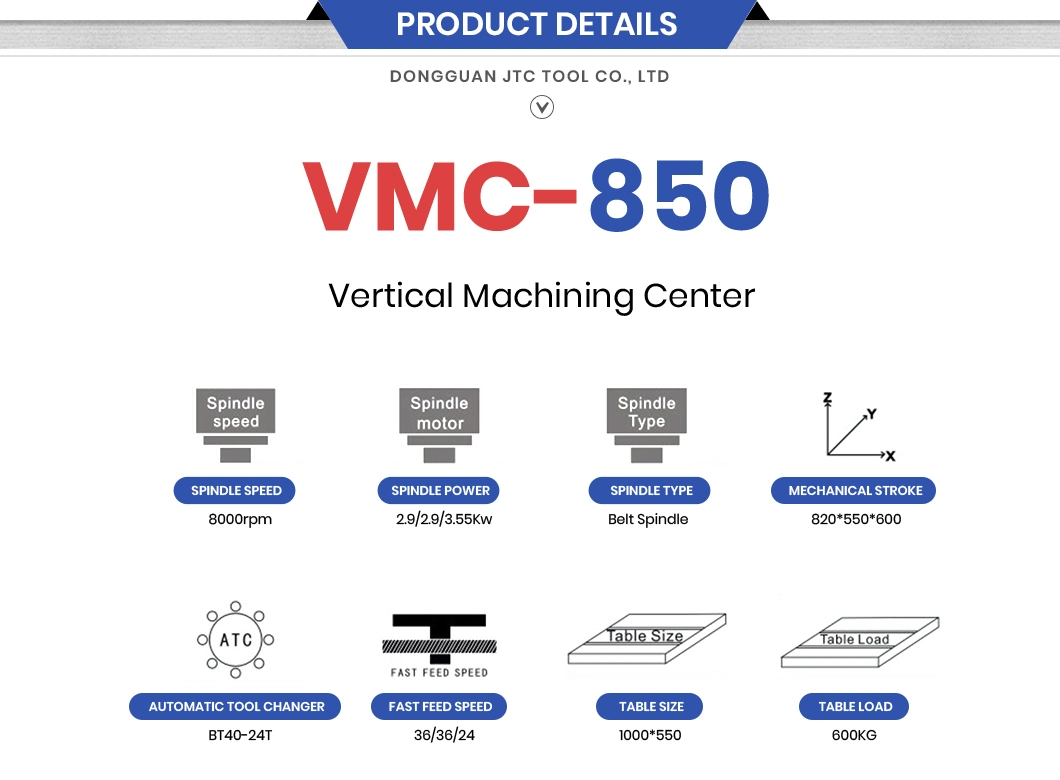

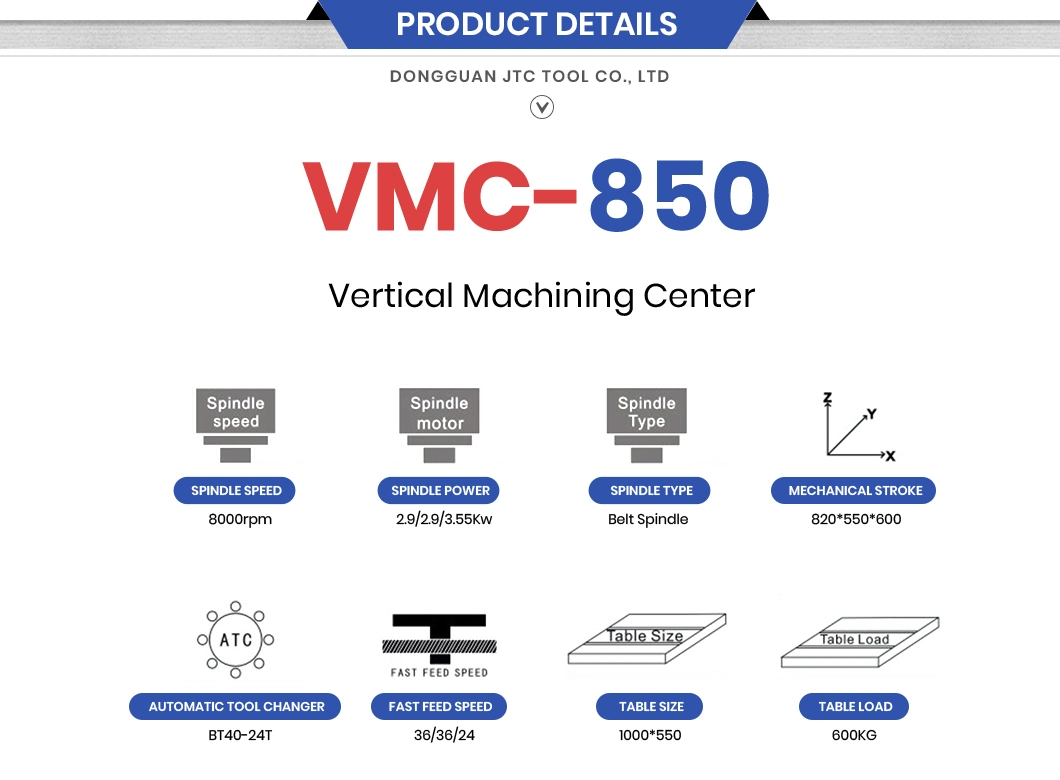

| Model NO. | VMC850 |

| Control Method | Closed-Loop Control |

| Numerical Control | NC |

| Processing Precision | 0.07~0.08(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | Used |

| Product Name | Vertical Machining Center |

| Model | Vmc850 |

| Keywords | Vmc |

| X/Y/Z Axis Travel | 820/550/600 mm |

| Motor Power of X/Y/Z | 2.9/2.9/3.55 Kw |

| Movement Speed of X/Y/Z | 36/36/24 M/Min |

| Distance(Nose to Workbench) | 130-730 mm |

| Motor Power of Spindle | 9 Kw |

| Speed of Spindle | 8000 Rpm |

| Taper of Spindle | Bt40 |

| Transmission of Spindle | Belt Type |

| Size of Workbench | 1000*550 mm |

| Max.Capacity of Workbench | 600 Kg |

| Weight | 5800 Kg |

| Measurement(L*W*H) | 2850*2390*2900 mm |

| Transport Package | Customized |

| Specification | Customized |

| Trademark | JTC TOOL |

| Origin | Guangdong, China |

| Production Capacity | 10000set/Month |

Product Description

DONGGUAN JTC TOOL CO., LTD.JTC TOOL 320 Table Travel Y mm 4 Axis CNC Wood Lathe Turning Machine Suppliers VMC850 CNC Turn Mill Center Machine China Vertical Machining Center Machine Product Description

What is CNC Vertical Machine Center?Vertical Machining Center (VMC) is a machining center in which the spindle axis and the rectangular worktable are set vertically, which is suitable for processing workpieces with high accuracy and precision, even with multiple procedures and complex shapes.What is CNC vertical machining center? CNC vertical machining center is a type of Computer Numerical Control VMC that has vertically oriented spindles that approach the workpiece mounted on a worktable from above and equipped with a tool magazine system and automatic tool changer.What is VMC in Machining?VMC machining refers to machining operations that utilize vertical machining centers (VMCs), which, as the name suggests, have vertically oriented machine tools. These machines are primarily utilized to turn raw blocks of metal, such as aluminum or steel, into machined components.

Product Parameters

Detailed Photos

FAQ

What equipment can you get from our Factory?* Milling machining center:Vertical Machining CenterHorizontal Machining CenterDrilling machineEngraving and milling machineGantry type machining center* Turning center:Double-spindle turning and milling centerDouble-spindle double-lane turning and milling compound centerCNC turning and milling compound centerTurning and milling compound center (true Y-axis power turret)* Turning center:CNC46C turning and milling seriesCNC46D Turret SeriesCNC46 gang knife seriesFlat bed CNC lathe* Five-axis machining center* CNC machining part* CNC ToolsWe support customization of the machines you need and provide you with good after-sales service.WHY CHOOSE DONGGUAN JTC TOOL CO.,LTD?QUALITY & RELIABILITYfirst time delivery.Quality cannot be inspected into a product. With that in mind we have a total quality mindset,throughout every process. Every person takes responsibility, there are no excuses. Certified to ISO 9001 SGS and with extensive quality procedures, we have been audited and certified by many authority agency companies in different industry sectors.QUICK RESPONSEWe recognise that in today's market, all companies are looking to reduce their margins with leaner production. With extensive machine resource, various add on services plus delivery and logistics to suit any requirement, you can be assured of our flexibility in offering a highly responsive and quick service. We have a proven track record of meeting and exceeding customer expectations.ADVANCED SYSTEMS & TE CHNOLOGYWe recognise that communication is the key and are working towards being a true Industry 4.0 Smart Factory with the latest IT hardware and our own in-house developed advanced ERP software. Such advanced systems will aid communication between us, the machine technology and you the customer, allowing us to be even more responsive to your requirements.Using the latest technology and specialist project management, we offer exceptional local serviceand performance on a national scale.